- Behind the Hoverboard Craze (BoingBoing) — Bernstein is interested in this phenomenon as “memeufacturing” — a couple of social-media stars (or garden-variety celebs) post viral videos of themselves using an obscure gadget, and halfway around the world, factories shut down their e-cig lines and convert them, almost overnight, to hoverboard manufacturing lines. Bernstein cites a source who says that there are 1,000 hoverboard factories in South China.

- neural-vqa — VIS+LSTM model for Visual Question Answering. Scroll to the end and see the questions it’s answering about photos.

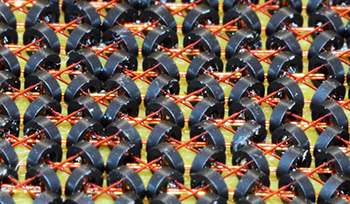

- Open Season in Editing Genes of Animals (NY Times) — “We’re going to see a stream of edited animals coming through because it’s so easy,” said Bruce Whitelaw, a professor of animal biotechnology at the Roslin Institute at the University of Edinburgh. “It’s going to change the societal question from, ‘If we could do it, would we want it?’ to, ‘Next year we will have it; will we allow it?’”

- RTS AI (PDF) — standard techniques used for playing classic board games, such as game tree search, cannot be directly applied to solve RTS games without the definition of some level of abstraction, or some other simplification. Interestingly enough, humans seem to be able to deal with the complexity of RTS games, and are still vastly superior to computers in these types of games. Talks about the challenges in writing AIs for Real-Time Strategy games.

"manufacturing" entries

Mengmeng Chen on demystifying manufacturing

The O’Reilly Hardware Podcast: Making manufacturing accessible.

Subscribe to the O’Reilly Hardware Podcast for insight and analysis about the Internet of Things and the worlds of hardware, software, and manufacturing.

In this episode of the Hardware Podcast, we talk with Mengmeng Chen, head of U.S. operations at Seeed Studio.

Discussion points:

- Chen’s work on—and thoughts about—the Pop-up Factory, a production line that manufactured connected devices on the floor of the Solid 2015 conference

- Ways to start manufacturing in Shenzhen without a gigantic first order

- Seeed Studio’s “Open Parts Library,” a standard library of approximately 1,200 parts that can be assembled quickly and inexpensively

- Differences between the component supply chains in the U.S. and China

- Seeed’s Wio Link Kickstarter campaign

Four short links: 30 November 2015

Chinese Manufacturing, Visual Question Answering, Editing Animal Genes, and AIs for RTS Games

Robert Bodor on digital fabrication

The O’Reilly Solid Podcast: Software intelligence in the manufacturing process.

Subscribe to the O’Reilly Solid Podcast for insight and analysis about the Internet of Things and the worlds of hardware, software, and manufacturing.

In this episode of the Solid Podcast, David Cranor and I talk with Robert Bodor, vice president and general manager for the Americas at Proto Labs, a rapid-prototyping service that’s been able to digitize large parts of the fabrication process.

Discussion points:

- Proto Labs’ contribution to the Pop-Up Factory at the Solid 2015 conference

- How Proto Labs infused software into the injection molding process, enabling 24-hour turnaround on tooling

- 3D printing vs. injection molding (that old battle)

- Parts of the process that defy automation

- The pros and cons of in-house prototyping

Brady Forrest and Renee DiResta on advising hardware startups

The O’Reilly Solid Podcast: Hardware startup success stories, pitfalls, and best practices.

Subscribe to the O’Reilly Solid Podcast for insight and analysis about the Internet of Things and the worlds of hardware, software, and manufacturing.

Hardware startups are starting to look like software startups: a lean company can bring a reasonably simple piece of consumer electronics to market for a few hundred thousand dollars.

Hardware startups are starting to look like software startups: a lean company can bring a reasonably simple piece of consumer electronics to market for a few hundred thousand dollars.

Behind that low figure are technological advances (like 3D printing and CNC machining that make prototyping faster and easier) as well as organizational advances — in particular, hardware incubators and accelerators that offer funding and help founders work their way through the product development process.

In our new episode of the Solid Podcast, David Cranor and I talk with Renee DiResta and Brady Forrest, co-authors (along with Ryan Vineyard) of The Hardware Startup: Building Your Product, Business and Brand. DiResta is vice president of business development at Haven, a marketplace for ocean freight shipping, and Forrest runs Highway1, a leading hardware incubator.

Forrest and DiResta take us into the trenches on a wide range of topics, including design for manufacture (DFM), idea validation, crowdfunding, cost control, marketing, packaging, and shipping. It’s a quick tour of the tricky areas of expertise that hardware founders need to develop. Read more…

How the IoT will transform manufacturing

The products of the future will impact not just factories, but all aspects of business.

Register now for Solid Amsterdam, October 28, 2015, where Dirk Slama will present the session “Managing the ‘Clash of Two Worlds’ in the IoT.” Editor’s note: this post is an excerpt from “Enterprise IoT: Strategies and Best Practices for Connected Products and Services,” by Dirk Slama, Frank Puhlmann, Jim Morrish, and Rishi M. Bhatnagar.

In some cases, a distinction is made between the industrial IoT and the consumer IoT. But when we talk about “Enterprise IoT,” our focus is less about specific application domains and more about openness and integration maturity.

In some cases, a distinction is made between the industrial IoT and the consumer IoT. But when we talk about “Enterprise IoT,” our focus is less about specific application domains and more about openness and integration maturity.

Here, we will take a closer look at some of the more industrial applications of Enterprise IoT, starting with a discussion about how IoT will transform manufacturing from the perspective of both product engineering and production technology.

Integrated production for integrated products

We believe that the IoT will have two main areas of impact on the current manufacturing landscape. The first concerns the organizational structure that is required to produce truly integrated IoT solutions. The IoT involves a clash between two worlds in which those in the machine camp and those in the Internet camp will be required to work together to create products that combine physical products with Internet-based application services. In an IoT world, many companies will discover that being just a manufacturing company or just an Internet company will no longer be sufficient; they will need to become both — or become subsumed in an ecosystem in which they play a smaller role. Read more…

Coming up at Solid Amsterdam

A look at our unified program for unified creators.

Register now for Solid Amsterdam 2015, our conference exploring the intersections of manufacturing, design, hardware, software, and business strategy. The event will take place in Amsterdam on October 28, 2015.

Creating a great product means knowing something about many things: design, prototyping, electronics, software, manufacturing, marketing, and business strategy. That’s the blend that Solid brings together: over our one-day program at Solid Amsterdam on October 28, 2015, we’ll walk through a range of inspiration and insight that’s essential for anyone who creates physical products — consumer devices, industrial machines, and everything in between.

Start with design: it’s the first discipline that’s called on to master any new technology, and designers whose work has been confined to the digital realm are now expected to understand hardware and connected systems as well.

Design at Solid begins with our program co-chair, Marko Ahtisaari, who was head of product design at Nokia from 2009 to 2013, and is now CEO and co-founder of The Sync Project. We’ll also hear from Thomas Widdershoven, creative director at Design Academy Eindhoven and co-founder of thonik, a design studio whose work specializes in interaction and motion design. Read more…

The 11 deadly sins of product development

Creating great hardware and software means avoiding these product-killing pitfalls.

Editor’s note: This post is an excerpt from “Prototype to Product: A Practical Guide for Getting to Market,” by Alan Cohen.

Thomas Edison famously said that genius is “1% inspiration, 99% perspiration,” and his observation holds true for product development. Developing “genius-level” products certainly requires inspiration, but the bulk of the effort is more like perspiration: work that benefits from insight and cleverness, but is also largely about not screwing up. Most product development efforts fail. It’s been my observation that failures are not usually due to a lack of inspiration (i.e., poor product ideas), but rather from mistakes made during the “perspiration” part.What follows is a brief catalog of the most popular ways to wound or kill product development projects. Most efforts that get derailed do so by falling into one or more of a small set of fundamental traps that are easy to fall into, but are also fairly avoidable. As an organizational construct, I refer to the specific traps as sins and the more-general negative impulses behind the sins as vices. And since these sins are often fatal, I call them deadly sins to remind ourselves of their degree of danger. Before we get into the specific vices and sins, let’s start off with the fundamental principle that lies behind all of these, a basic truth that largely determines success or failure. Read more…

Cottage industry 2.0

The O'Reilly Solid Podcast: Amanda Peyton of Etsy on the rise of craft.

Our new episode of the Solid Podcast brings us to Etsy, where David and I spoke with Amanda Peyton, a serial entrepreneur and product manager at Etsy, about the company’s role as a macro-community of micro-communities.

The connection between Etsy and Solid might not be obvious at first. Etsy’s specialty is the ultra-analog: handmade crafts that represent a return to an earlier era of artisan design and manufacturing.

But Etsy is emblematic of how Web platforms have transformed the relationship between product creators and product consumers. It offers rapid feedback from the market, quick discovery of new trends, and access to a large and diverse enough customer base that even extraordinarily niche products can be viable.

The result is a community of distributed manufacturers that’s responsive and efficient. For goods that can be made without a large, well-capitalized factory (even some electronics now fall into this category), Etsy may be the future of manufacturing. Read more…

A bigger and different way of looking at the IoT

Tim O’Reilly’s Solid Conference keynote highlights the capabilities that will let us shape the physical world.

O’Reilly’s keynote address at the Solid Conference in 2014 explored the human-IoT link. The talk expanded the scope of the IoT, making it clear this isn’t just about individual devices and software — we’re creating “networks of intelligence” that will shape how people work and live.

The talk has become an essential resource for us as we’ve investigated the blurring of the physical and virtual worlds. That’s why we decided to put together a text-friendly version of the presentation that’s easy to scan and reference. And since we think it’s so useful, we’ve made the text version publicly available.

You can download your free copy of “Software Above the Level of a Single Device: The Implications” here. Read more…

The Internet of Things is really about software

Our new report, "What is the Internet of Things," traces the IoT's transformations and impact.

One of the reasons that it’s ubiquitous is that it bears on practically everything. A few years ago, many companies might plausibly have argued that they weren’t affected by developments in software. If you dealt in physical goods, it was hard to see how software that existed strictly in the virtual realm might touch your business.

The Internet of Things changes that; the kinds of software intelligence that have already revolutionized industries like finance and advertising are about to revolutionize all the other industries.

Mike Loukides and I have traced out our idea of the Internet of Things and its impacts in a report, “What is the Internet of Things,” that’s available for free here.

As much as we all love the romance and gratification of hardware, the Internet of Things is really about software; the hardware just links the Internet to the rest of the world. If you think of the IoT as a newly developing area in software, it’s easy to draw out some characteristics of it that are analogous to things we’ve seen in web software over the last decade or so. Read more…